My new bike project — Cargo Bike

A year or two ago I drew up this design for a 20″ front, 26″ rear wheeled cargo bike and posted about it on this blog. This basic design is often called a cycletruck after the classic Schwinn sold around WW2.

The idea is that a smaller front wheel leaves more space for a big rack over the front wheel. The nice thing about this design is that the wheelbase is normal (so I can easily store the bike), but it has a pretty large hauling capacity. James Black extended this design in his cycle truck (built by David Wilson) by using a large boom over the front wheel to support the rack and 20″ wheels front and rear to allow for a low rear rack too. His cycle truck is probably the best of the compact cargo bike designs that I’ve studied or ridden.

One of my planned brazing projects has been to build a cycletruck of my own. I wanted to keep it simple, so I’m starting with a donor MTB frame. Yesterday I was going by Recycled Cycles and found the perfect frame on their free rack — a ~1990 Trek 800 in my size. To most people this is pretty junky, but for this project it’s exactly what I needed. The tubing is unbutted, so I can cut off the head tube and braze on a new one without worrying about where the tubing gets thin. It looks like it has already lived a good life, so I don’t feel bad chopping it up. I also have an old Bike Friday 20″ fork that will work nicely for the front wheel.

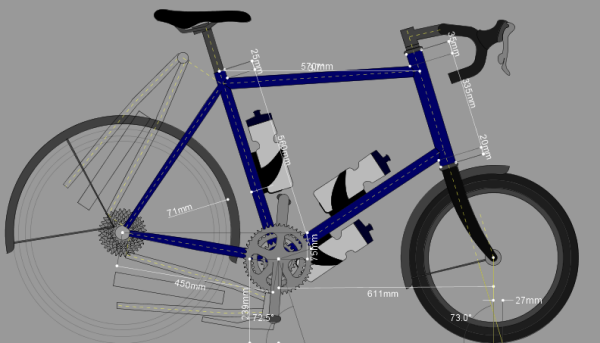

Here is the CAD drawing of what I plan on doing to it (click for big if you want to read dimensions):

The plan is to braze on a new head tube which is longer and steeper (73 degrees vs the 71 degree HTA on the bike today). Then I’ll run a 1 3/4″ x 0.058″ tube from the seat tube, around the head tube, and sticking out over the front of the bike. The original downtube will miter into this (or I’ll make a new downtube that goes from the BB to the base of the head tube). A roughly 18″ by 20″ rack made of 1/2″ tubing will sit over the front wheel.

It’ll be challenging for me, I haven’t done anything on this scale before. A few of the tricky bits are going to be making a nice through hole in that 1 3/4″ tube for the head tube and fixturing it to keep the frame well aligned during the brazing process. I’ll need to build tooling for some of that and plan on documenting my progress as I go. I have an aggressive goal of having this finished by the July 4th Cargo Bike Ride, but if I miss that target I won’t be surprised or feel too bad.

is that a 9/8″ headtube?

i think my original idea for this buildup avoided redoing the downtube as much as possible.

i also think the rack cantilevered across the downtube is a really good design.

nonetheless, i”m excited to see this thing come together!

The head tube that comes on the donor bike doesn”t matter since I”ll be replacing it. I”m putting a 9/8″ steerer on there, but the current frame is built for 1″.

My original plans also were simpler and kept the downtube in place. However I thought more about it and thought that it would be good to cantilever the rack off of the frame. This is the simplest way to build a James Black/David Wilson style cargo bike that I could think of.

Even for a simple design I think you”d want to replace the head tube. Mountain bikes typically have slack 71 degree head tube angles that aren”t going to be ideal for large loads. I also wouldn”t want to sleeve and extend such a crucial tube on the frame.

Fun project!

What’’s the reason for not building the main rack tube horizontal? Or, will the rack itself be horizontal, just this support tube is not? I”m guessing most loads don”t care if they”re carried on an angle, and it helps keep stuff on the rack, are there other reasons?

Oh -are you keeping the U brake on the chainstays?

I”m really excited to see this! Can”t wait to see how it turns out. I”ve hit the capacity limits of my porteur on several occasions, and I”ve got very interested in the Filibus/Muy Borracho/Bilenky/frontaloadontome style cargo bikes. They look like they”re nimbler and easy to store than the Long John style cargo bike.

Jimmy — good question on making it horizontal. I guess it looked good at a slight slope. It’’s also easier to aim for a slight uphill than to hit a perfectly level target (especially since this is my first time doing a miter like this).

Adam — This will still be smaller than most of the bikes that you mentioned. Those are some of my favorite types of cargo bikes though. At one point David Wilson was talking about getting the James Black Cargo Bike built as a production item. It would be really cool if that happened.

The U-brake is going, I”m going to braze on canti studs and use V-brakes. Actually, the U-brake studs will probably stay there, but I doubt that the brake will. Maybe I”ll turn it into a parking brake.

Alex,

Great! I really am looking forward to your progress on this. I was going to do something similar for a home brew long tail, but the combination of not having the torch or the workshop and the announcement of the BigDummy caused me to choose the production bike.

The schwinn cycletruck is a great place to update I think.

Back in my past I had decent luck with angle iron and 2×4 fixturing so when in doubt, do.

Nice idea, I”m interested to see how this turns out.

Although the picture doesn”t show it, the other half of the old downtube would probably be left in place butted into the top side of the “cargo” tube? Without another triangle there, the joint in the middle of the cargo tube would be under a lot of stress.

Mike — My plan is actually to replace the downtube with a new one going to the cargo tube/headset junction. I redrew the drawing with a level cargo tube and that change this morning.

Hi Alex:

I encountered your blog post here, and the project looks awesome.

I still haven”t finished the updates to my cargo bike that I”ve been planning, but it should be done in the next couple of weeks. Since you are working on this, I”ll give you the advance word on a product I found and a theory I”ve been pondering.

First, this pizza delivery bag is super cheap and should be very effective as a rack-top bag for the cycle truck:

http://www.deliverybags.com/product_large-pizza-jacket.htm

It is made of a kind of synthetic canvas treated with something to make it at least somewhat water repellant; it has 1″ thick insulation fill on all panels which acts as a cushion; it can be folded down when empty, or compressed with straps around the load; and it looks fine.

Second, I have a theory that connecting cargo loads with too much rigidity contributes to shimmy. I experienced the worst shimmy ever on the cargo bike when I strapped 35 pounds of newspapers to it very tightly. The unbraced cantilever seemed to find a nice oscillation that made it shimmy crazily even with both hands on the bars.

I suspect that similar loads attached less rigidly, that is, with the ability to slide a bit to avoid resonant effects, could eliminate this problem. I look forward to trying it once I have tailored the pizza bag to fit on the rack.

I came to this theory after carrying a giant cardboard box home on the cargo bike with a bunch of weight in it loosely, and found that it did not shimmy at all.

I suspect that engineering in some looseness with cargo carrying could benefit a lot of bicycles that have this problem, although one wants to avoid designing things that are subject to fatigue failure.

Cheers,

James Black

James — interesting comments on the shimmy. One of the things that I was drawing were support tubes that went from the outside corners of the rack to the bottom bracket. They wouldn”t add much triangulation, but they”d add a bit. I was worried that they”d sit too wide and interfere with my pedalling or sit too narrow and interfere with the front wheel. I”ll check it out once I”m at that stage.

Progress is being made. Last night I extended a Bike Friday 20″ fork to have a very long steerer. I might end up redoing it, I”m not very happy with how my brazing went.

I am wondering if the downtube is the best place to support the 1 3/4″. if you were to just look at the head tube and the support tube, and imagine the load you”d be carrying, the force would be pulling on the joint for the downtube. would it be better to be looking at something that is pushing down on that tube? I”m thinking of a tube that goes from the head tube/top tube junction to the back of the support tube.