Lots of projects brewing

Here is a single photo with 3 of the 4 that I’m writing about today:

First up is what I’m calling the Ivy-T. It is the replacement for my RB-T that I’ve been using as my commuter and road bike for the last few years. The new bike is sort of a joint project between Brandon Ives (IvyCycles) and I. He built the frame, I’m going to be doing the final bits on it (bridges, brazeons, brake bosses) and making the fork and rack. The geometry is basically a 56cm 1994 Bridgestone RB-T with the seat tube extended to 59cm, the top tube extended a bit, and a slightly sloping top tube. The lugs are Prugnat-style fromLong Shen. The tubing is Kaisei 019 (0.8mm/0.5mm/0.8mm butting, standard diameter) and the dropouts are Paragon verticals. It is a pretty light frame right now at around 3lbs, 12oz. I expect it’ll be more like 4 pounds once I’m done with it. Brandon’s work look very good and I look forward to finishing this one up.

Click the headtube for more photos:

Next up is a rack for Christine’s new bike.I’ve made about 80% of the deck, I still need to put in 3 more rays for the sunburst. We ordered a custom bag for her bike from Swift Industries. I’m going a little outside my normal with the rack and making the rack a little more pretty than what I would normally do. The pattern on the deck is influenced by anAhearne rackfrom the 2007 NAHBS.

John Speare gave Rory his beloved (or behated) Fuji Turd. Rory is turning it into a cycle truck, which I guess will probably become called the Turd Hauler (John calls the first cycle truck that we built the Stuff Hauler). Rory came over this morning and we mitered the cargo tube and top tube. When I built the first cycle truck a few years ago that process took me at least a full day. This time we did it in about 2 1/2 hours, including at least 30 minutes of searching for my 1 3/4″ tube clamp. Experience and a good milling machine do speed things up. Click the image for some iPhone quality images that Rory took of the process this morning.

Finally, I’ve been meaning to write about my new CNC mill for at least a month,but haven’t gotten around to it yet.

I bought this two months ago from Craigslist as a birthday present to myself. It is a Taig (made in the US) benchtop 3-axis CNC mill. What does that mean? The mill can move an object in two axis (X and Y),and then lower a tool (like a drillbit) from above in the third Z axis. CNC means that acomputer does the tedious work of moving the work around and cutting metal. Since computers don’t get bored it is happy tolots of timecutting out pretty intricate stuff. My first project with it was programming in all of the parts for the fork jig and making another fork jig for a fellow framebuilder. Once I have some feedback on it I plan on making some more. I’ve also used the CNC mill to make some simple fork dropouts (for yet another project) and lots of little fixtures.

In this photo it is making some brackets for the fork jig:

Here is what the computer shows while doing the heavy work:

The final result only requires a tiny bit of hand cleanup:

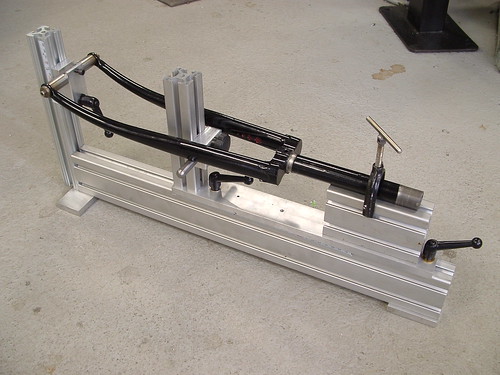

Fork fixture V2, almost all of the parts were made on the CNC mill.On the lower right corner you can see one of the brackets that the mill was cutting out above.

I plan in following up with more CNC stuff in a future posting, including some videos of it in action. For now I’m still mostly in the learning stage.

.JPG)